Concrete bored piers have traditionally been a common solution for foundation issues and underpinning. For a lot of engineers, it can also be the standard recommendation they provide for foundation repair.

However, it’s crucial for homeowners and property investors to understand the process, potential drawbacks, and available alternatives before making a costly investment in their home’s foundation. This succinct guide will provide clarity, highlight typical issues, and help you make a well-informed decision about your property’s foundation repair.

You aren’t locked into Concrete Piers

If your engineering report details concrete bored piers – and perhaps even shows these as part of the detailed drawings provided – it’s important to know that this doesn’t limit you to using concrete pier underpinning to rectify your foundation problems. Rather,

Often this is the typical recommendation an engineer might offer. It is not uncommon for them to use a standard template with generic drawings to illustrate the kind of solution you require. But this report usually doesn’t include a detailed engineering design – this is a separate requirement. And this is where you can ask for and investigate alternatives (e.g. with Foundation Solutions).

One of the most common modern alternatives available – screw pile systems such as those developed by Katana Foundations that we exclusively use – provide efficient, durable, and cost-effective solutions that may better suit your property’s needs.

Similarly the LiftRigMax system that we jointly developed is another modern example of going beyond the old concrete piers to provide homeowners with a solution to foundation problems that has many advantages.

Common challenges with Concrete Bored Piers

While effective in certain situations, bored piers can present significant challenges:

1. Extended Project Timelines

Concrete requires curing times typically between one to two weeks, with delays common due to weather conditions such as rain. This prolongs overall project timelines and can cause inconvenience. And this can be further exacerbated by poor workmanship on site.

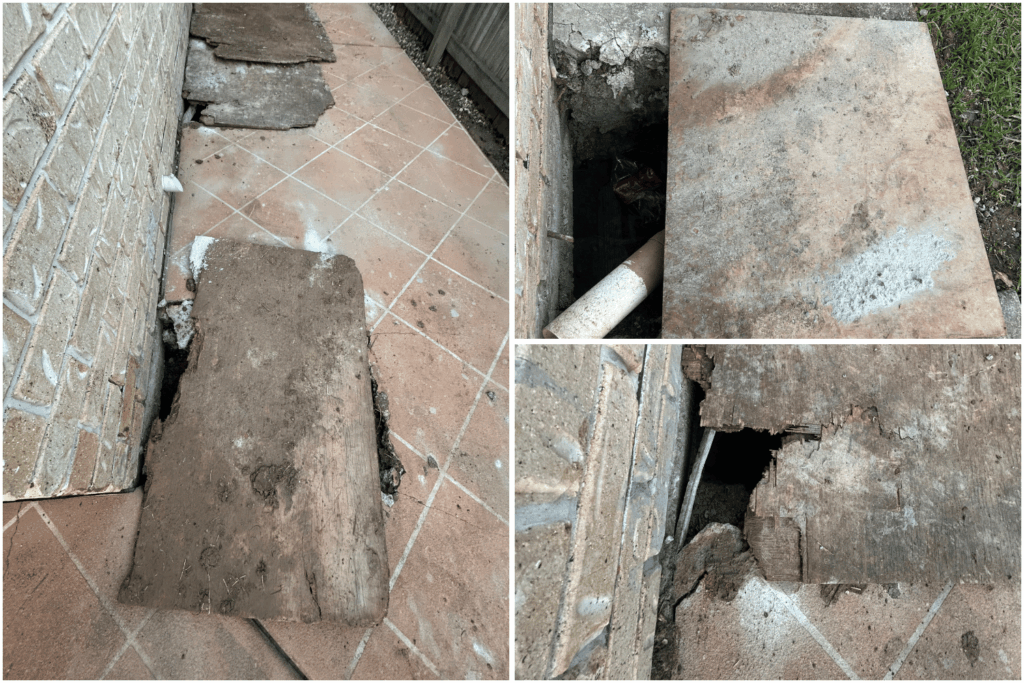

Example: Improperly covered concrete openings and rainy weather can lead to safety hazards and further delays.

2. Site Disruption and Cleanliness

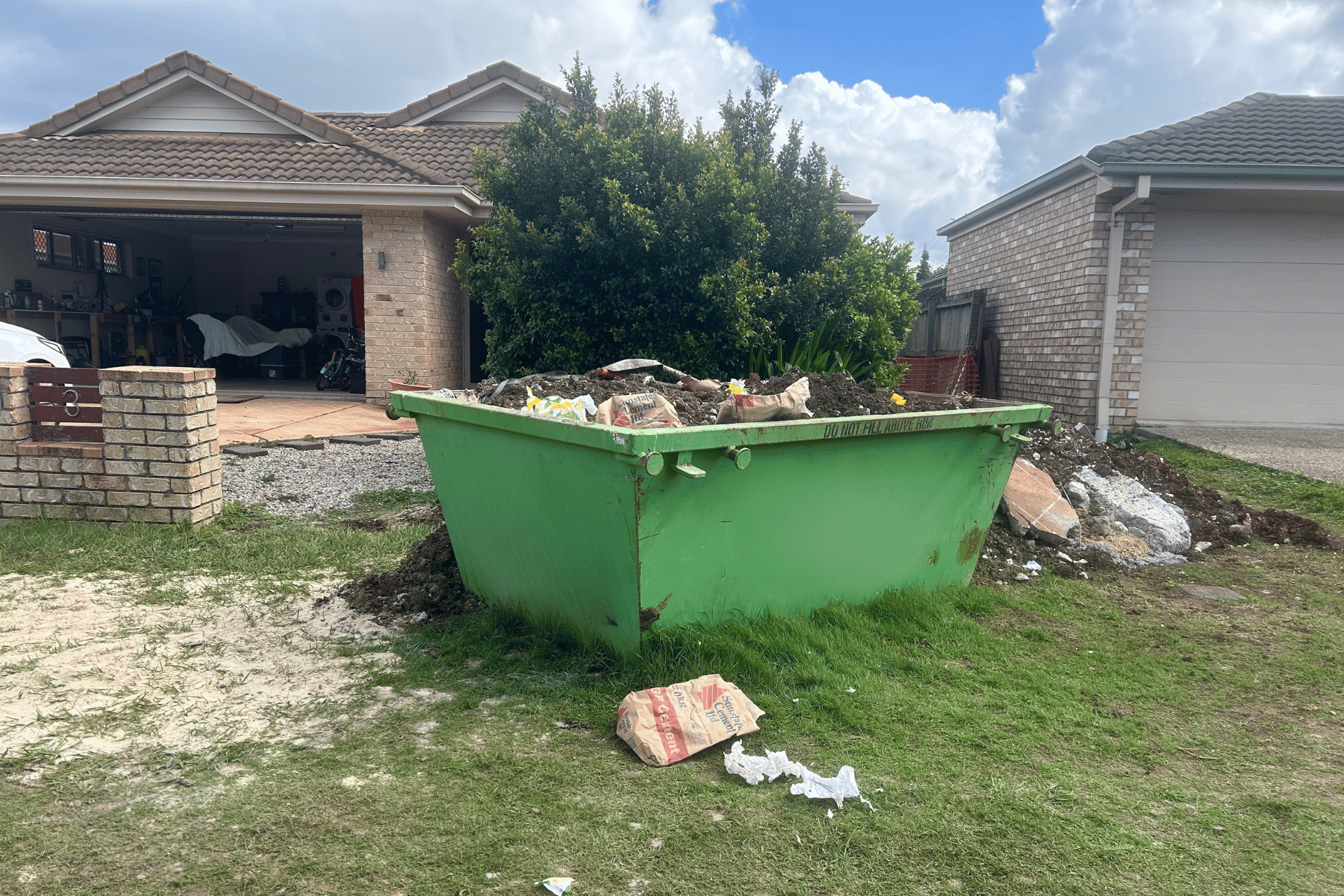

Significant excavation results in substantial spoil, creating mess and inconvenience if not properly managed.

Example: Large spoil heaps left unattended can negatively impact residents’ comfort and site safety.

3. Potential for Property Damage

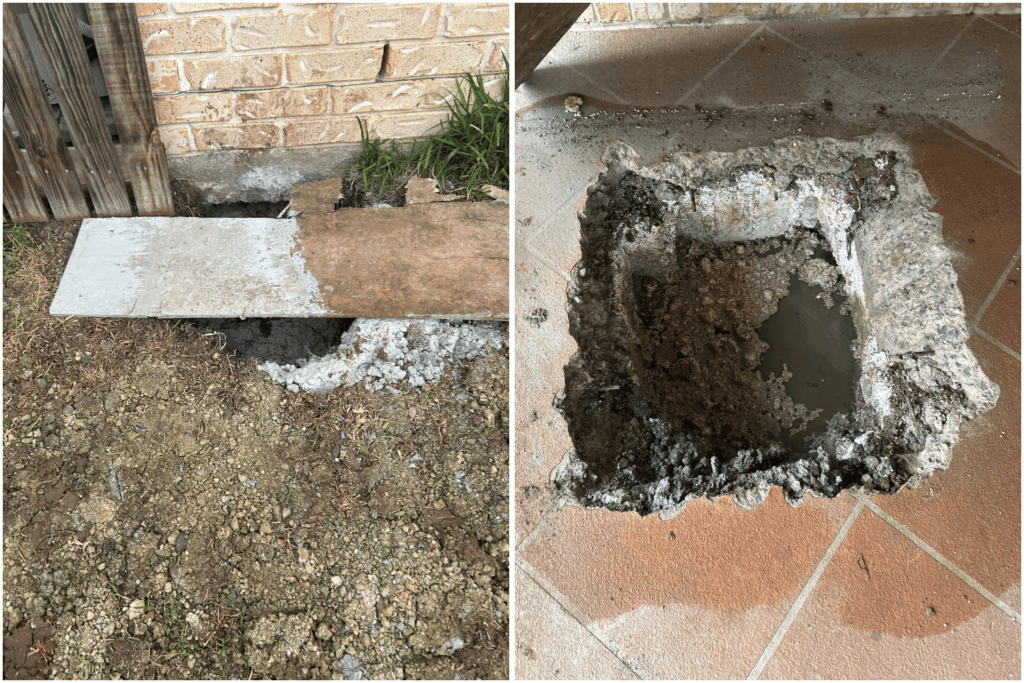

Extensive digging and jackhammering can cause unintended damage to surrounding concrete, plumbing, or landscaping.

Example: Poor workmanship, such as rough jackhammering of stencilled concrete or damaged plumbing, results in additional repair costs and aesthetic concerns.

4. Quality Concerns

Inadequate site management can lead to missed steps and structural integrity issues, including insufficient reinforcement in concrete headstocks or poorly maintained site safety measures.

Example: Freshly poured concrete headstocks lacking visible reinforcement or inadequate site protection boards raise serious quality concerns.

5. Weather-Dependent Delays

Rain and adverse weather can severely disrupt construction schedules, extending project timelines significantly.

Exploring Screw Pile Systems: A Modern Alternative

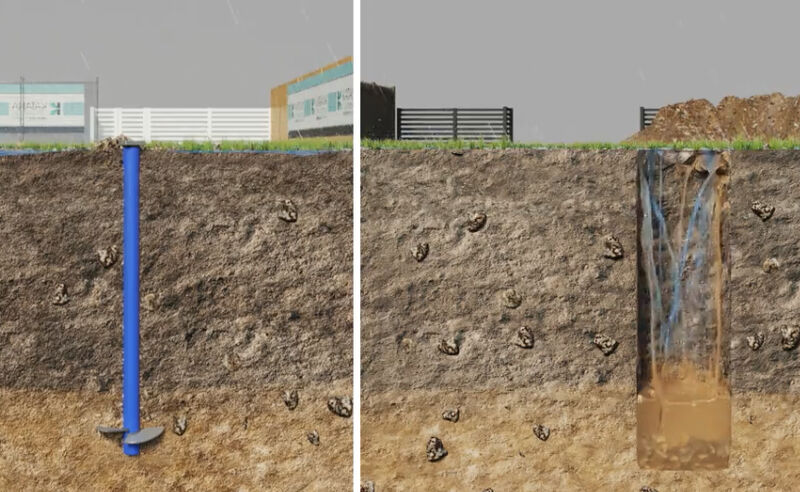

Screw pile underpinning systems, such as the LiftRigMax system combined with Katana Foundations’ screw piles, offer clear advantages:

- Rapid Installation: Screw piles can typically be installed and loaded within days, eliminating prolonged curing times.

- Minimal Site Disruption: Screw piles are installed with minimal excavation, significantly reducing the risk of site disruption and property damage.

- Immediate Load-Bearing Capacity: Unlike concrete, screw piles can support structural loads immediately after installation.

- Weather Resilience: Installation is possible even in adverse weather, preventing common delays associated with concrete curing.

- Environmental Benefits: Reduced excavation means less environmental disturbance and lower spoil removal requirements.

Our Customers’ Experiences

Our team at Foundation Solutions developed the LiftRigMax system with our engineering partner as a way to further optimise our underpinning projects and deliver even better client outcomes. Many of our clients have positively highlighted Foundation Solutions’ approach with glowing 5 star reviews:

“Nicole and Jason were absolutely wonderful to deal with, and actually worked with us to implement a solution that fixed our complex underpinning situation, rather than just superficial fixes.” – Tom M.

“After finding out that our house required underpinning we rang a number of companies seeking help, but it was Nicole at Foundation Solutions that put our minds at ease. From the get go Nicole helped us understand the process that we would be undergoing and went out of her way to assist us. She kept in constant contact with us throughout the process and made us feel comfortable, assured and understood. I would highly recommend Nicole and Foundation Solutions. They genuinely care about their customers and ensure they get the best results.” – Miranda G.

These testimonials underscore the professionalism and care we bring to every project.

Making an Informed Decision

When choosing a foundation repair method, it’s essential to consider all available options thoroughly. Foundation Solutions is committed to helping homeowners and investors choose the best underpinning method tailored to their specific needs.

For more information or a free consultation, contact Foundation Solutions. Our goal is always to empower you to make confident, informed decisions about your property foundations.